Custom Testing Tanks and Reaction Vessels

PolyFab provides:

PolyFab has been making testing and reaction vessels since the very beginning of our business. During that time we’ve done countless projects requiring pressure-resistant seams, precise increment labeling, and complex machining. Examples of our most commonly made testing tanks and reaction vessel parts can be found below. Don’t see what you’re looking for? Give us a call to discuss the specific nature of your project and see how we can help.

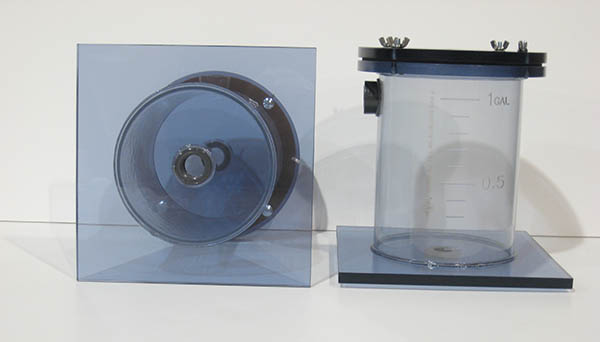

Pressure Tanks: Many of our clients need to test their products for water resistance or durability under adverse conditions. As an example, many electronic products are rated as waterproof up to a certain depth, in many cases this depth would be an impractical submersion point so manufacturers will use one of our pressure tanks to submerge their product and then apply pressure to simulate the necessary depth conditions.

Vacuum Tanks: Similar to a pressure tank, vacuum tanks are used to stress test products slated for application in adverse environments. The most common use for this type of tank is to test the seals of containers of connection points.

Phantoms: Phantoms, are specialty containers, filled with a specified-density liquid. These containers are used to calibrate MRI machines. PloyFab is cable of making these containers in accordance with nearly any set of required specifications.

Bioreactors: These specialized tanks are tailor-made for specific scientific applications. In recent years vaccine manufacturing has been greatly aided by the use of bioreactors, dramatically increasing the production rate of many vaccines previously using static culture or roller bottle technology. While the majority of these reactors are built primarily from a metal alloy, operators often prefer to see their reactions in process to maintain an appropriately high degree of quality control. PolyFab has developed significant expertise in forming and machining, top-of-the-line, impact-resistant windows a.k.a. “doors” out of premium grade clear polycarbonate allowing bioreactor manufacturers to offer their customers the capability of watching their reaction process as it happens.

Water Baths: A water bath, true to its name, is a container for water (or similarly inert fluid) often with special features to hold samples or smaller containers within it. Water baths have many applications and their construction is entirely dependent on their end-use. Whether maintaining temperature, heating and cooling reactive chemicals, or simply bathing samples prior to use. Whatever your specific use case PolyFab can create a water bath with the specific features your project requires.

Dip and Submersion Tanks: As the name suggests these tanks are used to test products in a submerged environment, without the addition of vacuums or pressurization. When it needs to be water-tight, make sure you’ve got a supplier who can build it right. PolyFab has been such a supplier for over 50 years, so give us a call to find out how we can aid your production process.

Custom Production Box Prototype

Ultra Thick Pressurized Testing Vessel

Pressurized Reaction Vessel

Lexan Diptank for Industrial Use

Scientific Waterbath Polycarbonate

Reaction Vessel Component

Chemical Reaction Vessel

Water Treatment Prototype

Founded in 1968, PolyFab provides custom engineered plastic fabrications. We work with many materials and specialize in clear plastics.

About

PolyFab makes custom plastic parts for scientific and industrial applications where the most precise and durable products are required.

Enter your Email

for free info about our process